Optimal Timing for Swamp Cooler Repairs

Performing swamp cooler repairs at optimal times can extend the lifespan of the unit and ensure efficient operation during peak usage periods. The best time to schedule repairs is typically during the off-season, before the cooling season begins, or after it ends. This timing allows for thorough maintenance without disrupting regular use and helps identify issues early, preventing costly breakdowns during hot weather.

Scheduling repairs in early spring ensures the cooler is ready for the upcoming season, reducing the risk of breakdowns during peak months.

Conducting repairs after the cooling season helps identify and fix issues before the unit is stored for the off-season.

Addressing repairs before a heatwave ensures optimal performance when cooling demand is highest.

Repairs during less busy times can lead to quicker service and less scheduling conflict.

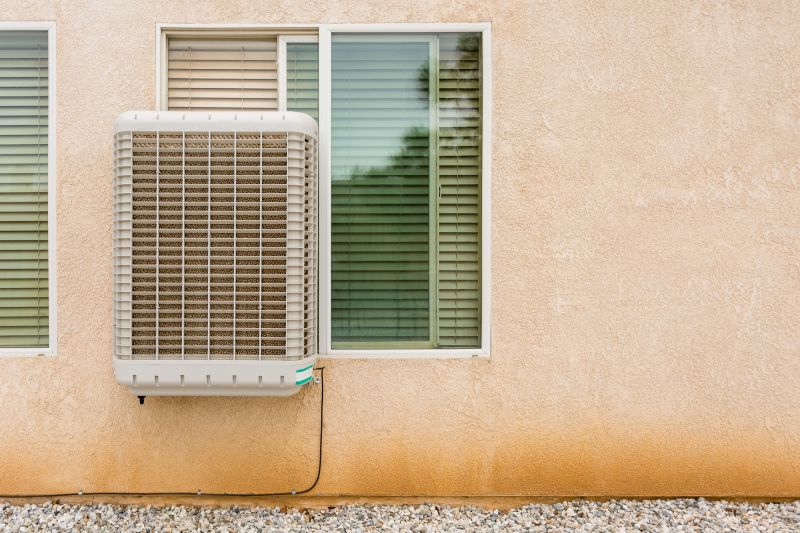

Technicians inspecting and repairing components before the season begins.

Assessing the unit after heavy use to identify wear and tear.

Preparing the cooler for high demand periods.

Ways to make Swamp Cooler Repairs work in tight or awkward layouts.

Popular materials for Swamp Cooler Repairs and why they hold up over time.

Simple add-ons that improve Swamp Cooler Repairs without blowing the budget.

| Optimal Repair Timing | Benefits |

|---|---|

| Early Spring | Prepares the unit for the season, reduces breakdown risk |

| Post-Season | Identifies issues after heavy use, ready for next season |

| Pre-Heatwave | Ensures maximum cooling efficiency during peak demand |

| Off-Peak Periods | Easier scheduling and faster service |

| Regular Maintenance | Maintains efficiency and prevents major repairs |

Swamp cooler repairs involve inspecting and replacing components such as pads, water distribution systems, fans, and thermostats. Proper timing of repairs can improve cooling performance, reduce energy consumption, and extend the lifespan of the unit. Regular maintenance is essential for optimal operation, especially before periods of high demand.

Inspecting and repairing swamp cooler components.

Ensuring efficient water evaporation for cooling.

Removing debris and checking for wear.

Verifying repair effectiveness and performance.

High-end options that actually feel worth it for Swamp Cooler Repairs.

Finishes and colors that play nicely with Swamp Cooler Repairs.

Little measurements that prevent headaches on Swamp Cooler Repairs day.

A 60-second routine that keeps Swamp Cooler Repairs looking new.

A frequent mistake in Swamp Cooler Repairs and how to dodge it.

Small tweaks to make Swamp Cooler Repairs safer and easier to use.

Lower-waste or water-saving choices for Swamp Cooler Repairs.

The short, realistic tool list for quality Swamp Cooler Repairs.

Timely swamp cooler repairs help maintain energy efficiency and cooling effectiveness. Regular inspections and maintenance can prevent costly repairs and ensure the unit operates reliably during the hottest months. It is advisable to schedule repairs before the onset of peak cooling season and after heavy use periods to catch potential issues early.